P8S System

Handling Robot

Probably the fastest fulfillment robot in the world.

The P8S Handling Robot combines high-speed motion control, vision-guided precision, and adaptive intelligence. Engineered to move faster, reach higher, and perform flawlessly 24/7.

Speed

The Handling robot drives with 1.5 m/second, the handling unit with up to 2 m/sec. It reaches up to 4 m high (or 10 m with mezzanine) and delivers up to 150 trays per hour to workstations or over 300 per hour in sortation mode.

Efficiency

The Handling Robot consolidates 30–80 trays in a single cycle, replacing up to 80 individual retrieval drives of conventional systems — dramatically boosting efficiency.

Automating replenishment

The Handling Robot also automates replenishment, collecting loaded containers from processing stations or directly from suppliers and placing items into the storage area with speed and precision.

New: Integrated cold-chain option

In addition, the Handling Robot with the cold chain option operates seamlessly across ambient, chilled, and frozen zones. Either as separate zones or as an integrated cold-chain process. With our new Tray Box Thermo system and optional automated passive cooling, products remain consistently at their target temperature throughout handling and transport.

Fact Sheet Handling Robot 4.0

Width: 1’040 mm

Length: 2’335 mm

Height: 3’765 mm

Weight (without load) ~750 kg

Runtime: ~8 hours, ~16hours available on request

Charging time: 1.45 hours, or 1.15 hours available on request, charges autonomously.

Uses LiFePo4 batteries for maximum safety.

Switches to low-power operation if not in use.

LiDAR based navigation enables driving precision of +/- <1cm.

LiDAR safety scanner detect objects and persons.

The handling platform has an integrated tray height measurement system.

Has a sophisticated pose estimation system for reliable interaction with P8S Containers.

Compatible with all P8S Trays and Containers.

Features a modular design to accelerate maintenance and repair.

Designed and built according to EN 1175 and ISO 3691–4.

Designed and assembled in Switzerland.

More system components

(Company highlights)

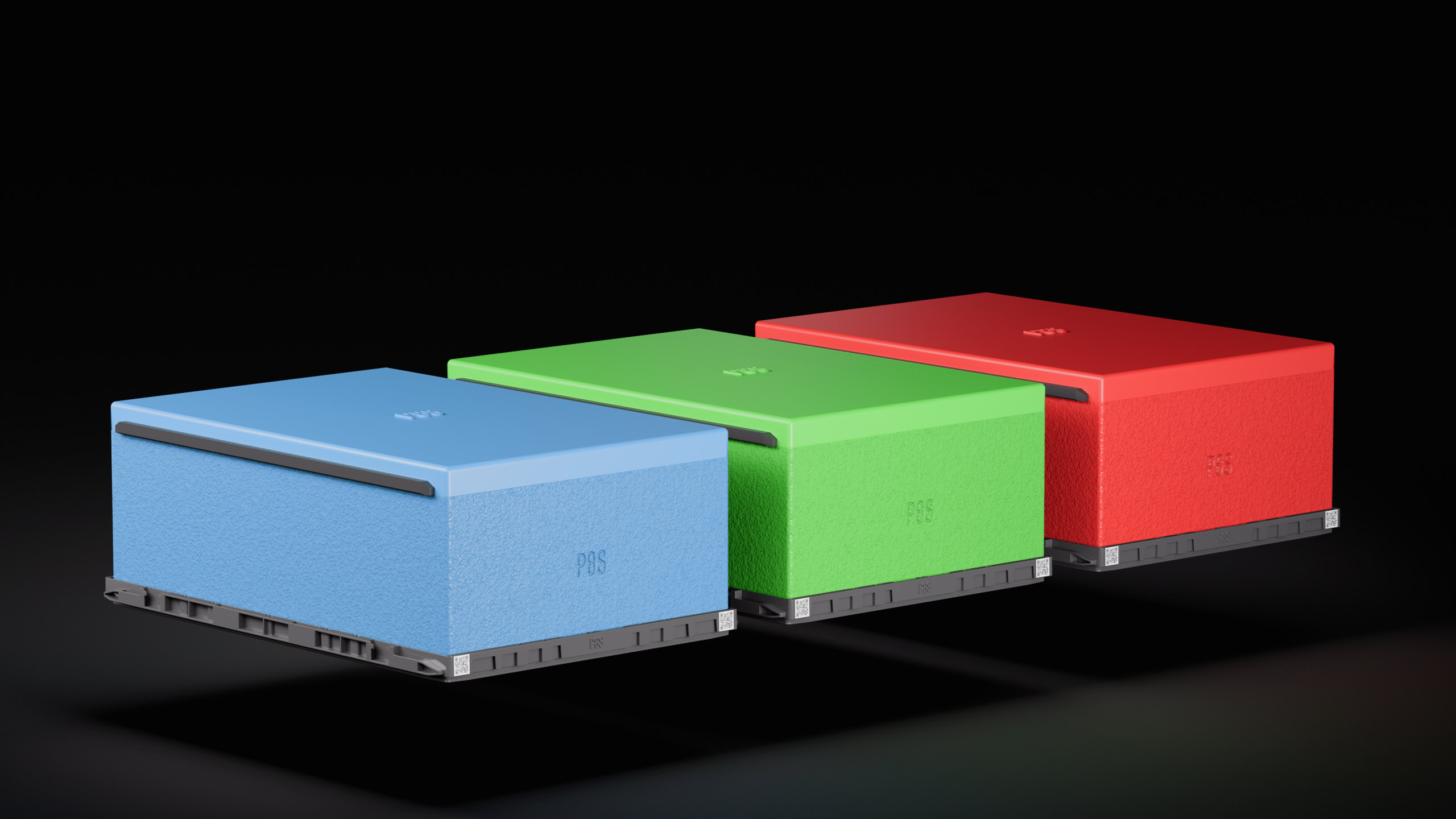

Containers

Containers are core to our logistics system. They enable high-density, flexible storage, handling, and transport, scaling effortlessly and empowering end-to-end automation. From receiving to delivery and 24/7 pickup.

Smart Tray System

More than just a load carrier. It holds products or cases, expands into a Tray Box with extension frames, and with a thermo extension runs a fully integrated cold chain. All in one system.

Process Stations

Fast picking and replenishment stations powered by artificial intelligence, software guidance, and pick-by-light. Available in multiple automation levels to fit your operational needs.

InfinityAI Software Suite

AI-optimised orchestration and real-time control software comprising of modules for Configuration & Design, Operation & Optimisation as well as for Performance Management

It’s time to talk.

P8S and Pick8ship® are trademarks of Pick8ship Technology AG. Patents are pending for the logistics system. The information contained on this website is protected by copyright and may not be used or distributed without prior written consent from Pick8ship Technology AG. Pick8ship Technology AG makes no representations or warranties, either explicit or implied, regarding the accuracy, completeness, or timeliness of the information or views provided. All content on this website is for informational purposes only and may be updated from time to time. The information does not constitute an offer or any other binding declaration of intent. Under no circumstances shall Pick8ship Technology AG, its directors, employees, advisors, or development partners be liable for any damages or losses of any kind arising from or in connection with the information on this website.