Industries

Industrial & Assembly

Market situation

The industrial assembly and equipment market in Europe is a roughly 100 bn Euro large market with 50% of companies represented by medium and large SMEs. The main sub-segments are Machinery & Equipment (45%), Electrical & Electronic Control Systems and Equipment (30%), Tools assembly (15%) and Robotics & Automation Systems assembly (15%). Market growth is modest, but a major transition towards next generation assembly is ongoing.

Expectations

The automotive, industrial, and tool assembly sectors in Europe are entering a new era marked by modular, flexible, robotics-driven, AI-enabled, and vision-integrated systems, making them capable of handling small series and customized production at scale.

Implications for logistics

P8S highlights for Industrial & Assembly

(Company highlights)

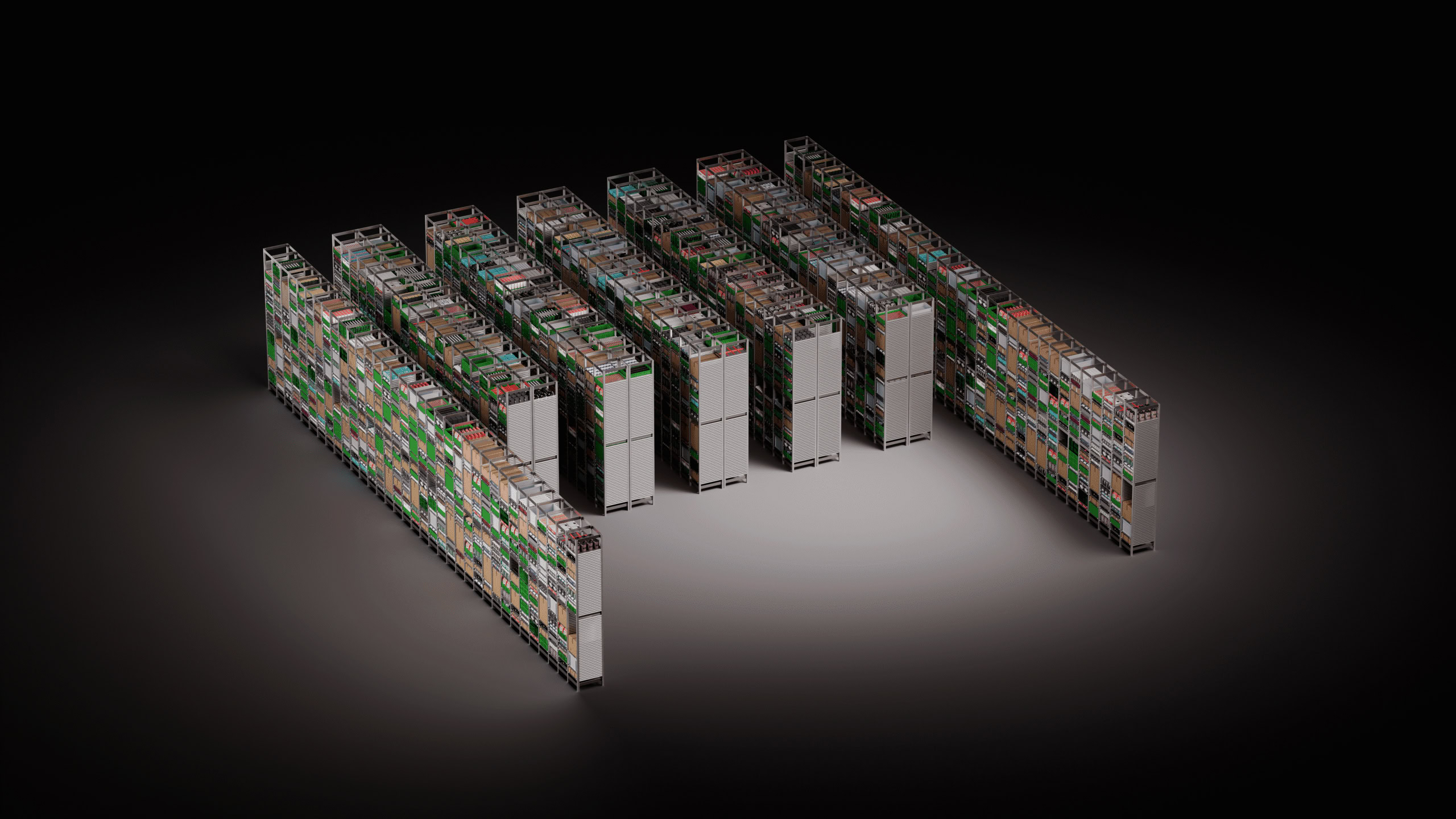

No fixed shelves, but flexible, high-density storage in Containers with the Smart Tray System.

Our vision for Industrial & Assembly

Robotic storage, sorting and picking, highly modular. Flexible and fast replenishment processes, with multi-purpose robotics. Workstations that can be quickly reconfigured for different needs and high density storage and transport in smart containers for ultra-fast handling. Digitized assembly leveraging containers, Pick-by-light and software guidance for efficient and error free assemblies.

All-in ONE Fulfillment

with ultra-flexible, high-density storage and multi-purpose fulfillment robots for efficient end2end transport & automation.

Containers, smart Trays and KLTs, end2end

enable efficient handling of small and large products: eaches, cases, and assemblies with automation at every level. They cut handling steps, reduce process time, and support robotic sorting, cross-docking, zero-handling receiving, and streamlined production.

Seamlessly integrated network

A unified network that links suppliers, central storage, and production — minimizing handling steps, accelerating delivery, and ensuring optimal preparation for fast, cost-efficient assembly.

Powerful software and AI

A digitized material flow, with containers as flexible transport and buffer units — optimized for automated sorting, zero-handling-receive, fast pickup, and efficient assembly, all powered by advanced software and AI.

It’s time to talk.

P8S and Pick8ship® are trademarks of Pick8ship Technology AG. Patents are pending for the logistics system. The information contained on this website is protected by copyright and may not be used or distributed without prior written consent from Pick8ship Technology AG. Pick8ship Technology AG makes no representations or warranties, either explicit or implied, regarding the accuracy, completeness, or timeliness of the information or views provided. All content on this website is for informational purposes only and may be updated from time to time. The information does not constitute an offer or any other binding declaration of intent. Under no circumstances shall Pick8ship Technology AG, its directors, employees, advisors, or development partners be liable for any damages or losses of any kind arising from or in connection with the information on this website.